About a year ago I was asked by an old friend and client, Steve Gold, to help with a project in Kellé, Niger. Steve has done 46 solar photovoltaic systems for the Wildlife Conservation Network to support conservationists and biologists around the world who are working to save endangered species, and the Niger project represented a substantial leap in scope and complexity over his previous projects. I signed up not knowing exactly what was involved, and it has exceeded my wildest expectations in terms of the significance of the project, the complexity of the systems, and the time involved.

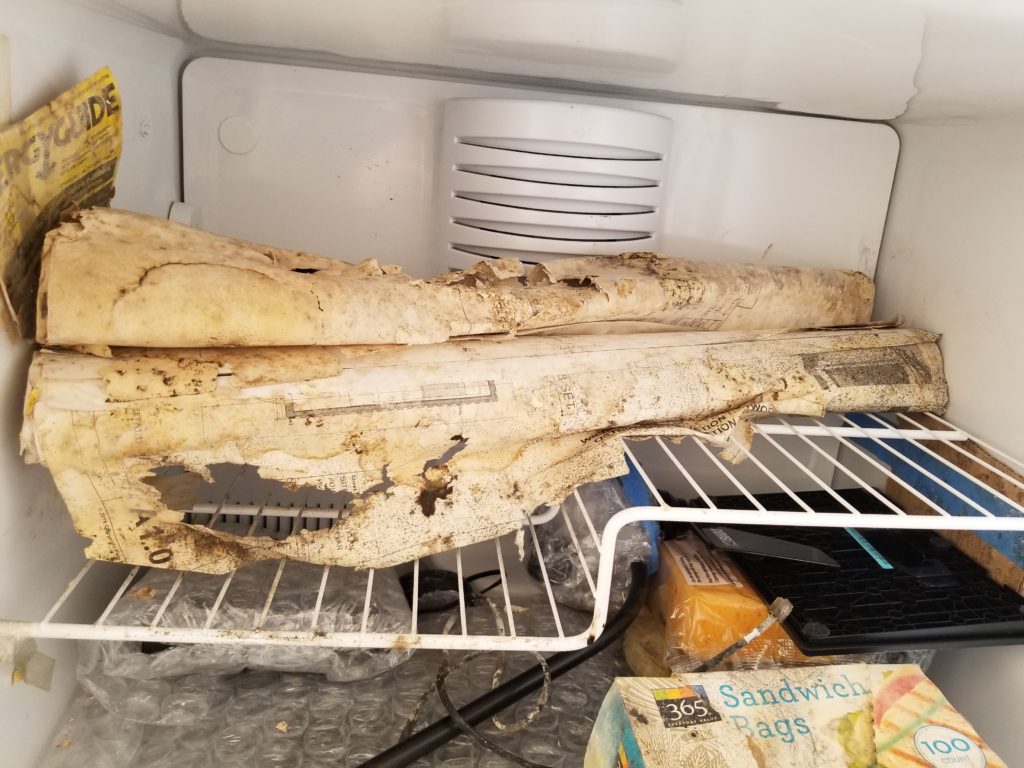

The North African Ostrich once populated large areas of the Sahel and Sahara in northern Africa. Measuring up to 9 feet tall it is the largest bird on the planet. Only something like 24 known breeding adults now survive of this subspecies, Struthio camelus camelus. When populations descend to these numbers a lack of genetic diversity tends to magnify weaknesses and make the group more prone to disease and reduced breeding success, a problem that has hampered efforts to increase the population. Nigerien conservationists in Kellé desperately need better means to solve the many difficulties they experience in trying to breed new generations from captive birds, including deteriorating brooding behaviors, low egg viability, and early chick-hood diseases. All of these problems stem from a variety of stresses suffered by these birds, due in part to the necessity of protective captivity, exposure to caretakers, and susceptibility to disease. Among the many problems – lack of refrigeration to keep veterinary medications viable.

The Sahara Conservation Fund and the Wildlife Conservation Network, for whom Steve is a longstanding volunteer, have stepped in to assist Nigeriens in the effort to bring this bird back by providing a full range of infrastructure improvements. Despite habitat challenges and a history of predation, there are outstanding success stories in achieving just such a goal. The model in this case has been a program led by the San Diego Zoo to re-introduce the California Condor. Their efforts, as translated to the Sahel, will rely on several key technical factors:

The Sahara Conservation Fund and the Wildlife Conservation Network, for whom Steve is a longstanding volunteer, have stepped in to assist Nigeriens in the effort to bring this bird back by providing a full range of infrastructure improvements. Despite habitat challenges and a history of predation, there are outstanding success stories in achieving just such a goal. The model in this case has been a program led by the San Diego Zoo to re-introduce the California Condor. Their efforts, as translated to the Sahel, will rely on several key technical factors:

- Use of commercial incubators and hatchers designed for the poultry industry to increase egg and hatchling survivability

- Careful control of environmental factors, such as heat, humidity and disease vectors, meaning:

- A climate-controlled environment in an area that often sees temperatures of 115 degrees F, utilizing mini-split heat pump systems

- A source of clean, hot water to maintain sanitation, to be pumped from a new well 1 km away

- A clean laboratory-like environment

- 24/7 monitoring of equipment and environmental data

- Most crucially, a supply of electricity in an area that has none

All of these goals require a facility equipped with a variety of systems and features – the nitty gritty of architecture – all designed for efficiency in order to work with solar power. In my most hopeful moments I imagine that this kind of technology transfer could model a system of sustainable energy production for the region, and that rural electrification in the Sahel could take the form of solar power.

The design has grown a bit since the generation of this rendering. We now have an array of 110 photovoltaic panels, mounted on a canopy both to shade the buildings from the sun and to keep the panels up out of harm’s way. These are supported on a system of steel trusses designed to withstand the uplift of possible 95 mph winds (one of the factors in dealing with this project has been the relative lack of weather and other data for this site, which has led us to be as conservative as we think we can get away with). Under the canopy are 4 shipping containers, outfitted for 1) PV equipment (including 17,000 pounds of sealed batteries), 2) an office, 3) a hatcher room, and 4) an incubator room. All of the systems and equipment in these containers are pre-installed. The everyday operational doors, and all connectors for utilities and ventilation, are concealed behind the container shipping doors so that when loaded onto a ship for transport these containers have no protrusions or holes.

The design has grown a bit since the generation of this rendering. We now have an array of 110 photovoltaic panels, mounted on a canopy both to shade the buildings from the sun and to keep the panels up out of harm’s way. These are supported on a system of steel trusses designed to withstand the uplift of possible 95 mph winds (one of the factors in dealing with this project has been the relative lack of weather and other data for this site, which has led us to be as conservative as we think we can get away with). Under the canopy are 4 shipping containers, outfitted for 1) PV equipment (including 17,000 pounds of sealed batteries), 2) an office, 3) a hatcher room, and 4) an incubator room. All of the systems and equipment in these containers are pre-installed. The everyday operational doors, and all connectors for utilities and ventilation, are concealed behind the container shipping doors so that when loaded onto a ship for transport these containers have no protrusions or holes.

I have donated over 250 hours of billable time to this project in the last year, and it has been immensely rewarding to be part of a highly effective team dedicated to an environmental project of this significance. Besides Steve, who oversees everything, and the internationally reknowned team of biologists who are our “clients,” we have

I have donated over 250 hours of billable time to this project in the last year, and it has been immensely rewarding to be part of a highly effective team dedicated to an environmental project of this significance. Besides Steve, who oversees everything, and the internationally reknowned team of biologists who are our “clients,” we have

- Carpentry, electrical and insulation crews giving time at highly reduced rates

- A donated site for construction

- $175,000 of funding from the Sahara Conservation Fund

- Photovoltaic systems provided at or below cost by Outback Systems

- A completely donated $30K mini-split HVAC system from Lennox Industries

- A commercial incubator provided at cost by NatureForm

- Hatchers donated by the St. Louis Zoo (compliments of Bill Houston, a major contributor to the science team)

- A $25K truss system being built by Bob’s Ironworks in Oakland for $10K

- Volunteer efforts from a host of highly talented professionals – ranging from graphic designer, to architect, to fundraiser, to genetic restoration specialist

- And many more

If you read the SCF newsletter linked above, you will see acknowledgements for some of the contributors, and the list grows longer each week. (By the way, please feel free to look into making your own donation to the project via the Wildlife Conservation Network Donation Page – we will need to raise another $75,000 in the next few months to complete the project, commission it fully assembled, load it onto trucks and ship it to Africa! If you would like to take advantage of my offer of 1 hour of professional services/consultation as a gift for each $1,000 donated, “dedicate” it to PRA. Donations can also be made at our crowdfunding site, to be announced in a subsequent post). You can also visit our Facebook page on this project.

I will post updates on the progress of construction here in the next few months. In the meantime, here are some construction progress photos: